Yes, 7/16 OSB (oriented strand board) is commonly used for wall sheathing in residential construction, providing structural support and a stable base for exterior finishes.

Oriented Stand Board (OSB) is famous nowadays because it can be used as an alternative to plywood.OSB sheets are heavy compared to plywood, and the cost is much less than plywood. OSB sheets are becoming more popular than plywood for wall sheathing, roof decking, and floor underlayment.

Is It Possible to use 7/16 OSB for Walls Sheathing?

OSB sheets are made of water-resistant resins, which makes them as sustainable as plywood.7/16 OSB can be used as wall sheathing.OSB is thicker and more prominent in size than plywood. It doesn’t bend over like plywood as it’s made by compression, yet OSB is more nature-friendly than plywood.

It will work neatly for wall sheathing as long as it’s protected from the sun and water. It can hold the wind and bad weather but expands in contact with the water for too long, which takes a long time to dry out.

7/16 Wall Sheathing Installation Tips

For wall sheathing with 7/16 OSB, try choosing quality material with a span rating for the application. In wall construction, the sheathing panel can be installed horizontally or vertically. Please ensure each board is spaced 1/8 inch gap between them to avoid expansion bending. Make sure to maintain ½-inch bearings in each panel edge.

When attaching the sheathing panels with the wood structure, choose 8-penny sharp nails to fasten the 7/16 OSB with the woods because of its thickness. If you decide on nails smaller than 8 mm, the pins won’t even go through the sheathing wall. Pay proper compassion to nail and spacing the panels, or it won’t be a quick view because the boards won’t stand parallel to the structure. It will create weaves that won’t appear considerable at all.

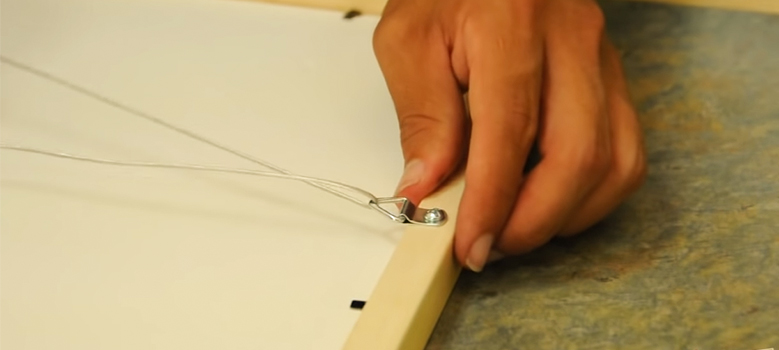

Now attach the panel to the structure with a fastener. Make share to gap 3/8 inch gap from the panel edges and 6-inch gap to each pin; You can gap 12 inches in the intermediate support of the panel. The gap between fasteners varies from the area you are building the house. If the site is windy, you must add more pins to secure the wall.

When you have secured the wall with fasteners, the following process is to start the nailing process. First, nail the panels in the intermediate section 12 inches apart, then complete the nailing pattern with 4-inches each nail.

When you place another panel beside the nailed board, the nailing sequence needs to be changed to make the panels uniform.

Position the other panel and ensure the space gap, then lightly tap on the corner of the wall to place it correctly and attach fasteners. Now start the nailing process just from the next edge of the previous panel, keep removing the stuck nail and putting the 8 mm nails from top to bottom, then nail the 1st intermediate stud following the 2nd stud, and lastly, the other edge. Now nail the top and bottom row of the panel to complete the process.

Frequently Asked Questions

What size Should OSB have been used in Exterior Wall?

For exterior wall sheathing, the thickness of the panels needs to be chosen, depending on the area you are building the house. Usually, 7/16 sheets are used for exterior wall sheathing as they are affordable and available in the market. But depending on the area, if It’s too windy, it’s hard to maintain the pressure of wind using 7/16 inch walls because these are very lightweight and won’t be able to prevent the calamities. In that case, 3/8 walls or, if possible ½ walls can be an excellent match for exterior wall sheathing.

What size of Plywood should use on the top Sheathing?

For shed floors, a few different kinds of plywood are available, including pressure-treated plywood, OSB, and conventional 5/8 inch t/g sheeting. It, therefore, offers strength but must be covered with completed flooring. The plywood will be used in a shed, no other flooring will be laid on top.

I advise using 3/4 inch pressure-treated plywood instead of 5/8 inch and OSB, though both will work. Pressure-treated plywood can withstand the moist conditions typical in a storage shed, and it will also last for the duration of the shed.

What is the cheaper alternative to OSB sheathing?

OSB is the cheapest material and can be used for Sheathing, which is made from compression of timber wood. But Plaster wood can be an alternative to OSB, though it’s also made from reduction. But the particles are mainly recycled wood, so it can’t be as sustainable as the OSB. Another cheaper alternative can be EPS and XPS as they are rigid Foam insulation. These products are suitable for sound prove rooms but can’t be reliable for wall sheathing.

Can I drywall over Osb?

Yes, you can drywall over OSB to change the room’s texture. Also, you can put on screws through the plaster. Nevertheless, It’s challenging to detect studs under the plaster wall to stick the screw.

What is Stronger? CDX Or OSB?

CDX is a type of plywood made from wood veneers, which makes it more robust and durable than OSB sheets.

Conclusion

Compared to plywood, OSB doesn’t give a fine texture as it is made of timbers. But it’s easy to paint and plaster over it because of Its rough surface; It doesn’t need much sanding to apply plaster or sheet walls. Many experts consider OSB better than plywood because it doesn’t expand in humidity and moisture.