Room dividers are the main function of freestanding walls. In addition to water supply lines and electrical wires, freestanding walls also contain some mechanical elements. Walls need lateral support as they increase in height. It is less necessary to provide lateral support for a wall with a height of three feet than for a wall with a height of six feet. It is usually more convenient to hire professionals, but if you learn the technique yourself, you can stabilize it yourself. The following method will help you stabilize a freestanding wall properly. For more information, read this article.

How to Support a Freestanding Wall

Room dividers are mostly freestanding, visually delineating spaces without doors. It is possible to install electrical wiring and water supply lines within freestanding walls, just as they can under standard walls. Unlike a standing wall, which can bear weight, framing members can have virtually any dimension. With increasing wall height, lateral support becomes increasingly important. The lateral reinforcement required for a wall 2 feet high is less than the reinforcement required for a wall 7 feet high.

⦿Load-bearing walls and “partition” walls (not load-bearing walls) are located in different parts of your house. While freestanding interior walls do not bear loads, they are not attached to the ceiling or adjacent walls, unlike the standard partition walls. As a result, the side walls will need additional support, either on top or at the bottom of the wall.

⦿The freestanding wall will be strengthened by adding end wall support: The simplest method of adding lateral reinforcement to a freestanding wall is to support the end walls of the wall. Another wall usually accompanies the main freestanding wall as a side wall. An end wall forms a “T” or an “L” shape at either end of a freestanding wall and serves as a side brace to support the wall from sideways. Depending on the desired open feel, the end walls can be half-height or the same height as the freestanding wall.

An in-Floor Reinforcement System

⦿Alternatively, if space constraints prevent an end wall support from being used or if you simply prefer not to build one, you can build the lateral support in the floor itself. A minimalist appeal is offered by in-floor reinforcement, but the end of the wall frame must be attached to the joists in order to ship through the existing subfloor.

⦿There must be at least one end stud through the depth of the floor joists on both sides of the wall. In order to provide additional support, the end studs must be doubled. Due to the inadequate support provided by framing nails, end studs are attached to the joists by long carriage bolts. End studs are prevented from shifting by adding side supports.

⦿If you want to know the exact specifications of in-floor support, consult an engineer. You could usually add end members to the joists by doubling two-by-four wall studs. Then, you would nail two pieces of lumber, measuring both their dimensions and adjacent to the double-end studs, onto the floor joists.

The Framing of Freestanding Walls

Frames are used for freestanding walls, just as they are for other interior walls. Except for the two double studs used at the ends of the in-floor reinforced wall, the bottom wall plate sits flat on the subfloor between the two end walls. Stump spacing should be 16 inches when installing standard wallboard on the wall frame. Wall plates of similar dimensions are attached to the studs at the top of the wall.

The Following Tools Will be Needed

To prepare for bolting wall studs to floor joists, predrilled holes in the subfloor are required with a reciprocating saw. Using an old-fashioned hammer and nails is just as handy as a framing nailer when it comes to building walls. During the process of creating a freestanding wall, studs will need to be cut using a circular saw.

Instructions for Supporting a Freestanding Wall

It is possible to make a free-standing pallet wall from wood or vinyl. As a room divider or backyard fence, pallet walls are often used as freestanding structures. The pallet wall will allow you to more efficiently utilize the large room you have. You can use a freestanding pallet wall to keep your kids entertained. There’s a freestanding wall in my living room that’s been there for a few months, and everyone loves it for its decor and use. Detailed instructions are given below on how to build a freestanding wall.

Step1: Find out how long the free-standing wall will be. Your first step should be to determine the size of your pallet wall. There is usually a similar height between pallet walls and doors for free-standing pallet walls.

If the larger length doesn’t serve any purpose, you won’t need to make it longer. The next step is to cut some pieces of wood for the pallet wall. After determining the height, cut the pieces accordingly. This step requires a handsaw. Build the free-standing pallet wall with two pieces of pinewood.

Step 2: The wood pieces need to be drilled and studs should be installed. Clean the corners with 80-grit sandpaper and install a few studs. It is necessary to stack your cut plates after they have been cut side by side. The spacing between studs should be about 15 inches.

Make a list of the number of studs you intend to use, then count them. Based on this number, cutting will be required. Using sandpaper is the best approach when removing burrs from wood pieces. Sandpaper with an 80-grit rating is the best choice for smoothing wood pieces.

Step 3: The plates need to be drilled and the screws need to be placed in the holes. A 1/16-inch drill bit and an electric drill are needed for the next step. Placing the frame plates so that the wider sides of the plates face upward is the best way to arrange them.

You will need to drill the studs where you marked them previously. You can place screws in these holes later by drilling two holes at each stud. In addition, you’ll need to install a screw tip. Once the wood glue has been applied to the studs, install the panel. The same process should be repeated for each mark on the stud.

Step 4: Sort the pallets according to their sizes Using one plate, make a freestanding pallet wall by using it as the top plate. The paneling needs to be placed on the studs now. The extra paneling can be removed with a utility knife if there is any left. Lastly, there are a few steps to complete.

Pallets must be arranged in a particular way to make a freestanding pallet wall. Pallets must be positioned and arranged in a certain order. You will need 3-inch bolts for this step. Take a hammer and use these bolts to arrange the pallets.

Step 5: In addition to being a fence, you can also use this. Rather than changing the entire pallet wall, you’ll just have to make it a bit bigger. You can use a freestanding pallet wall as a fence if you plan to cover a side of your house with one. For the free-standing pallet wall to be fully functional, it will need to be extended in both height and width. You can enjoy some quality time in your hot tub or spend some time in your backyard more privately. You will appreciate this free-standing pallet wall once you have made it because it can be used in so many ways.

How to Stabilize a Freestanding Wall

Freestanding Wall Stabilization Tools: Some essential tools make it easy to stabilize a freestanding wall. The tools you need to build a freestanding wall include cutting, drilling, framing, and building the wall itself.

⦿Using a measuring tape ⦿Knife and scissors ⦿Using a reciprocating saw ⦿a drill machine⦿ Screws and nails ⦿Hammer Pipe wrench

If built and supported properly, a freestanding wall enhances a room. The following steps will help you stabilize a freestanding wall. A freestanding wall can be stabilized quickly by following these steps.

⦿The first step is to assemble the wall frame: The first task you had to complete was to assemble the wall frame. Build the deck with deck screws by maintaining the frame style and rails. Once the window stiles are positioned between the rails, screws should be used to secure them. Assemble the wall and window frames together.

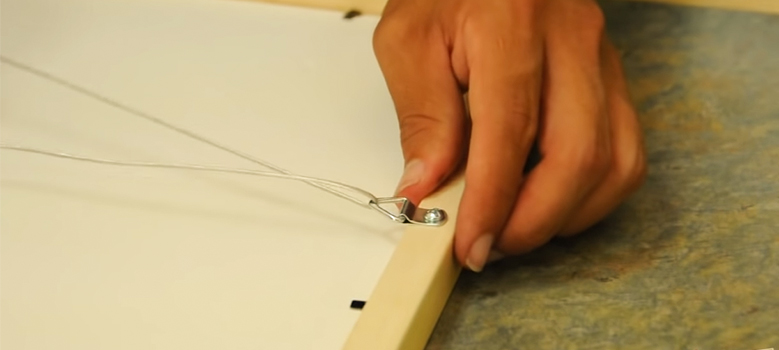

⦿The second step is to attach the pipe or wire: Attach a pipe or electrical wire to the underside of the window rail if you wish to keep a water pipe or electrical wire contained. Keeping it hidden and protected will ensure its safety. After that, the window stiles need to be centered below each other. The lower frame rail should now be drilled with two diameter holes. Connect the wire or pipe by inserting it through the holes and tightening it.

⦿The third step is to install the window rail skins: Glue and nails or a hammer can be used to attach the top and side frames. Once the window rail skin and window stile skin have been installed, the window frame can be closed. You need to take your time here; use the hammer gently to set the proper level.

⦿The fourth step is to create panel skins: Creating the panel skins is the next step. A measuring tape and pencil should be used to mark the opening window. A jigsaw should be used to cut the holes inside the lines.

⦿The fifth step is to fix the frame skins: You need to apply wooden glue on one side of the frame in order to fix it to the wall. You should then nail the frame tightly to the skin once it has been placed squarely on the frame. Fix the other skin in the same manner on the other side of the frame.

⦿The sixth step is to trim the skin panels: A skin panel needs to be trimmed to the surface of the frame skins. Once the corners of the panel have been squared, use a handsaw to ensure they are straight.

⦿The seventh step is to assemble the pipe with the lower frame: The required pipe must be assembled using a pipe wrench. Using the lower rail as a starting point, thread the pipe.

⦿The final step is to look at everything: Complete the final appearance after stabilizing the freestanding wall. Make the surface smooth by filling in nail holes. Let it air for a while before painting the wall.

Frequently Asked Questions

How to Anchor a Freestanding Wall?

Because the short wall at the top of a staircase is there to prevent people from falling down, it needs to be stronger than the one in the middle. In most cases, flooring joists are used as anchors for these walls. The plywood is extended below the subfloor, then screwed to the joists. The screws should be 2 inches long, with a distance of 12 inches between them. When the plywood has been secured, you can install drywall directly over it.

Conclusion

There can be no connection between a freestanding wall and a building. A distance of more than 3 feet, however, could pose a risk without adequate lateral support. Creating a freestanding wall is not a complicated undertaking, but it must be done correctly. It is possible to stabilize a freestanding wall yourself. However, if you do not have the skill in stabilizing the wall yourself, we recommend hiring professionals.